Automating Borehole Quality Assessment

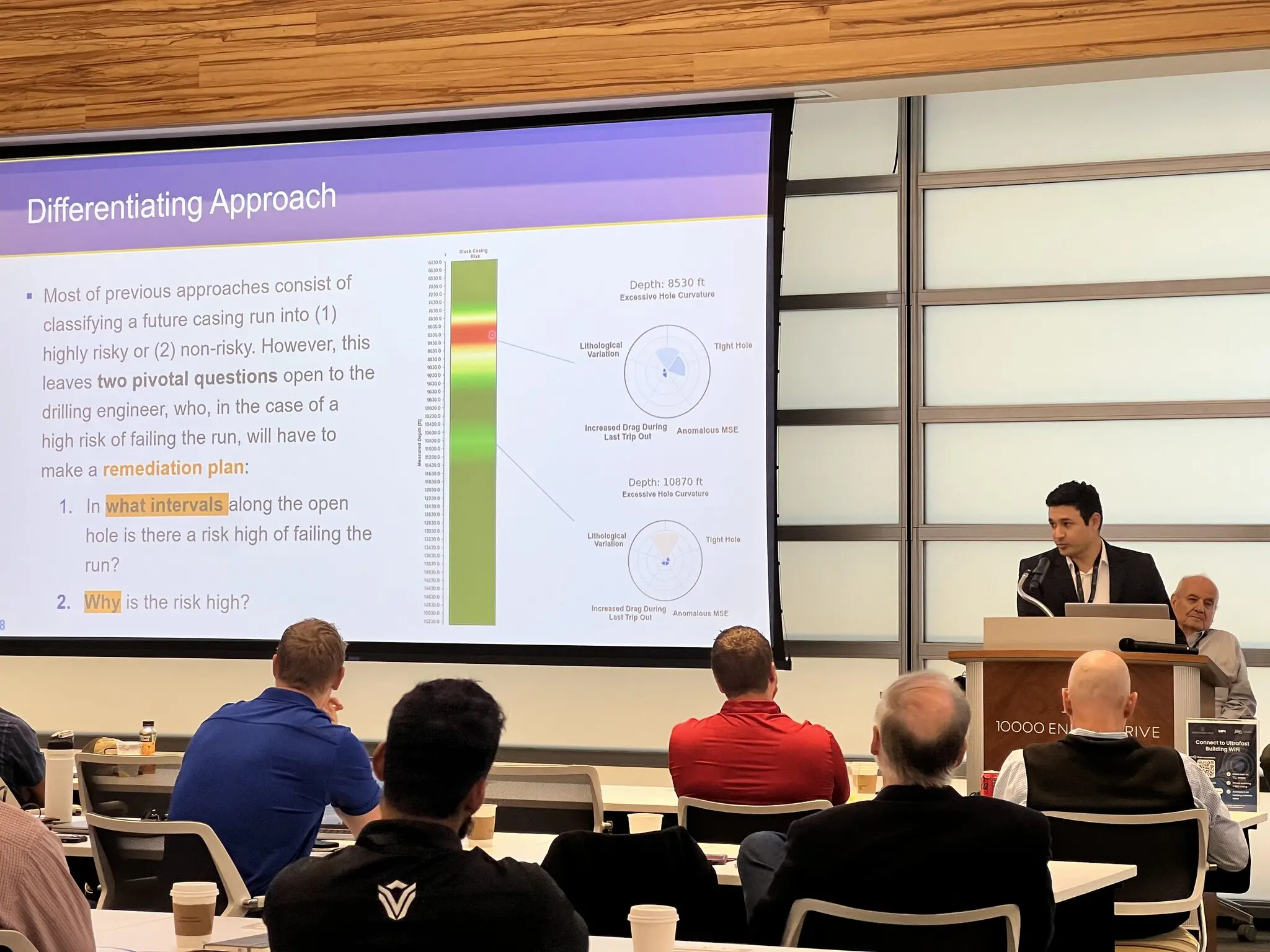

September, 2024.We had a highly productive session at the 2024 IADD MWD/LWD Forum in Houston. Together with a highly talented fellow researcher, we presented our project on avoiding casing run failures through automated borehole quality assessment. The model we developed provides the drilling team not only with accurate predictions of the borehole's readiness to accept casing, but also with clear insights into the associated risks, pinpointing their locations along the wellbore and explaining their causes.

By implementing this tool, the drilling team can potentially achieve significant cost savings. For example, they can proactively prevent casing run failures by addressing high-risk areas with targeted conditioning trips, while avoiding overly conservative measures when unnecessary. These savings could range from $500,000 to $10 million, particularly by preventing catastrophic events like the need to abandon part of the borehole and drill a sidetrack.

We are currently working on enhancing our predictive tool by incorporating data from LWD ultrasonic borehole images. These data significantly improve the model's interpretability by offering a visual representation of geometric patterns that could cause severe restrictions when running the casing, such as borehole spiraling. Additionally, they help reduce uncertainty in some indirect measurements, such as the gamma ray log, by determining whether variations in natural radioactivity correspond to prominent ledges where the casing could become stuck.

More details on this project will be presented at the 2025 SPE/IADC International Drilling Conference in Stavanger, Norway. Stay tuned for further updates!